Temperatures in Wilmington are not letting up any time soon, so does your Air conditioning system stand a chance? As a mobile mechanic I see all types of common mistakes from owners and also common component failures when it comes to your vehicle’s air conditioning system. Here are a few a my top noted human errors I have personally noticed;

- “buying a can of Freon and applying the whole can to the system”.

- “Trying to replace a Ac compressor without any special tools”

- “trying to add large amounts of Freon to the system till it gets cold”

Now let’s go over why we should not do these 3 things I listed above.

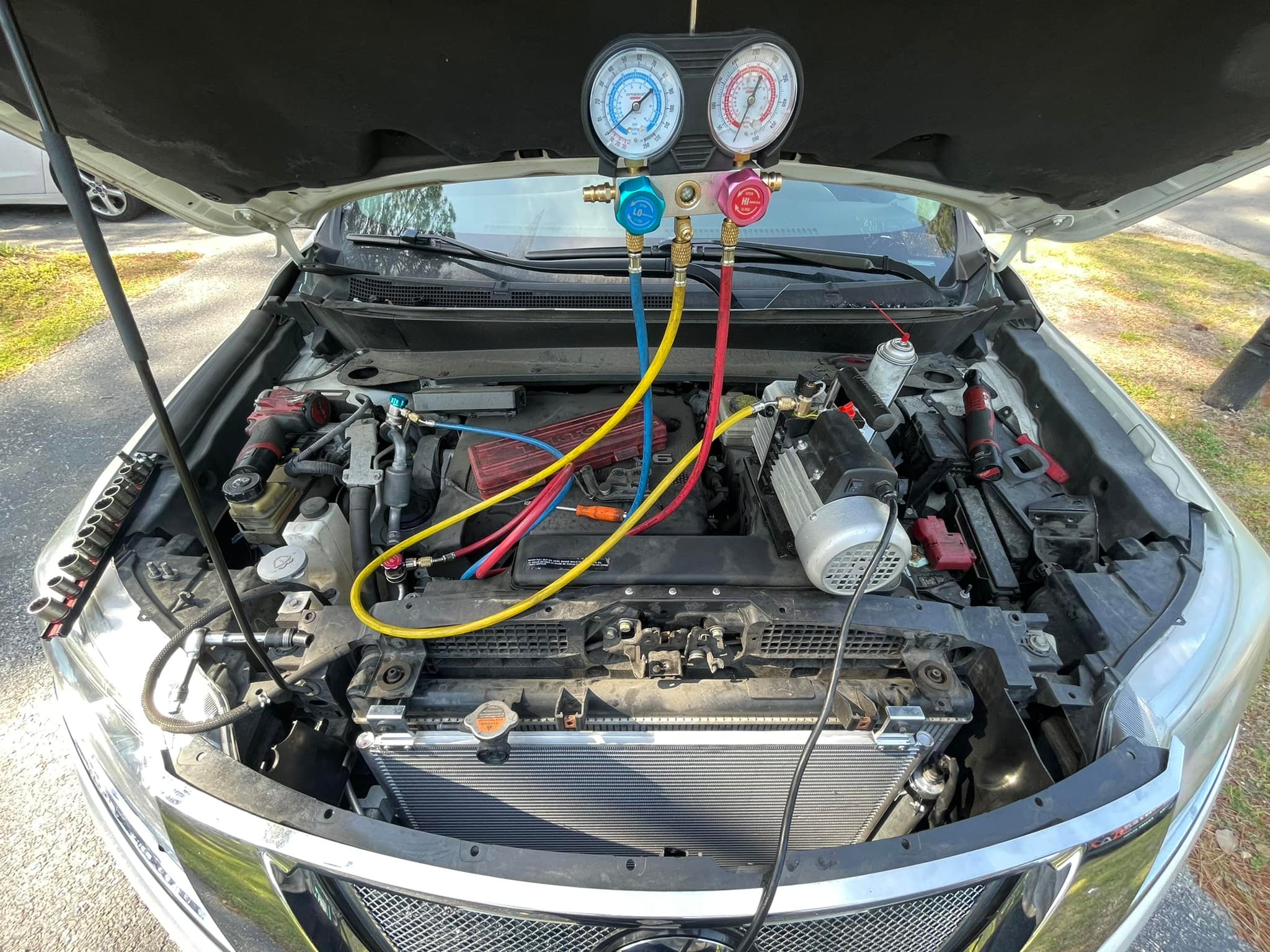

- Every vehicle requires a different amount of Freon. For example a v8 pick up truck may take 32 ounces and a small compact sedan may only need 22 ounces. Also unless you have proper gauges for both the high and low side there is no possible way to know you have put enough Freon in to get correct pressures. Gauges I mention look like the ones I am using the in the first picture at the top of this article.

2. Although sometimes a compressor may look like a very achievable task, think again there are some fine details you must know. If you don’t evacuate moisture, the acids formed by high temperature reaction of refrigerant and moisture will destroy the condenser, the evaporator, the compressor and any control valves in the system as well as any aluminum lines. In other words, every part of the entire system. So it is a very doable job, but for the average consumer buying a vacuum pump for one car is not a investment they want to make.

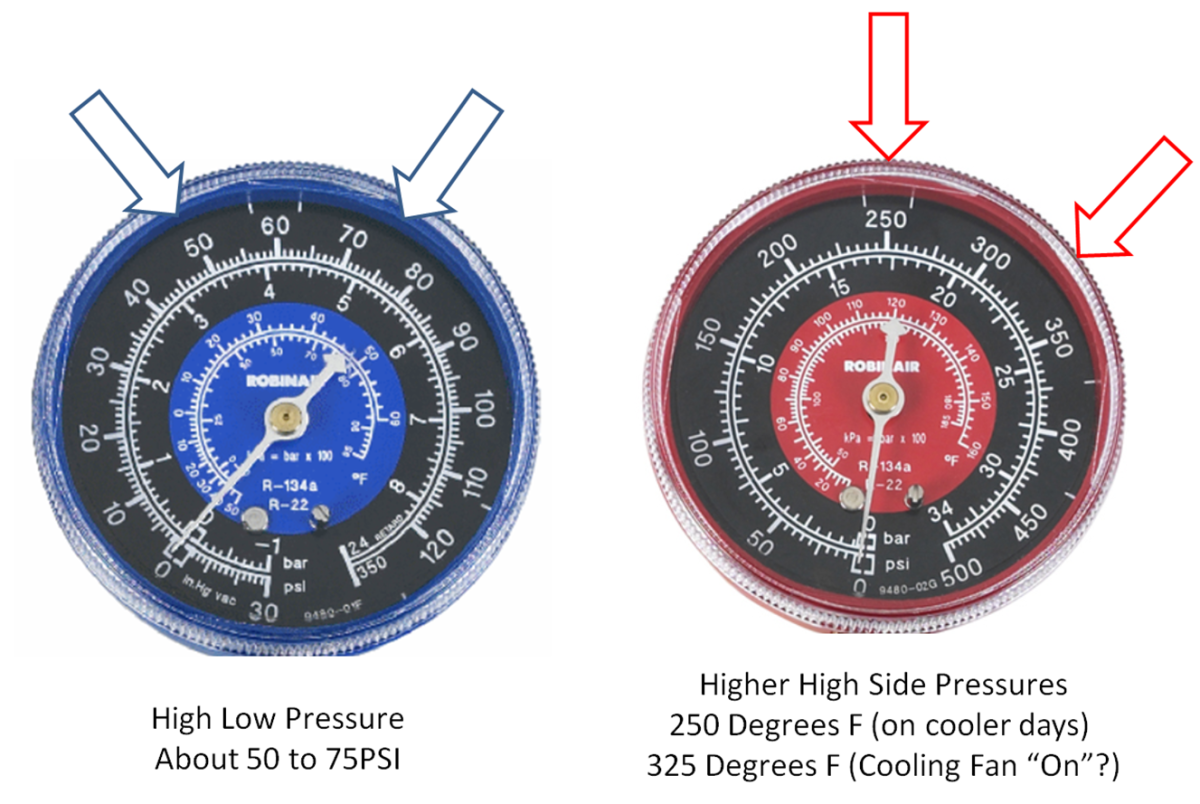

3. Overcharging your system can cause your compressor to short cycle, this would mean the compressor would click on and off way to frequently. If you overcharge your system you will also have higher head pressures of an overcharged system, this will have a tendency to overfeed the evaporator, thus decreasing the superheat. If the system is overcharged more than 10 percent, liquid can enter the suction line and get to the suction valves or crankcase. This will cause compressor damage and eventually failure.

Now that we have got the human errors out of the way lets go over some of the major mechanical failures I find on vehicle air conditioning systems.

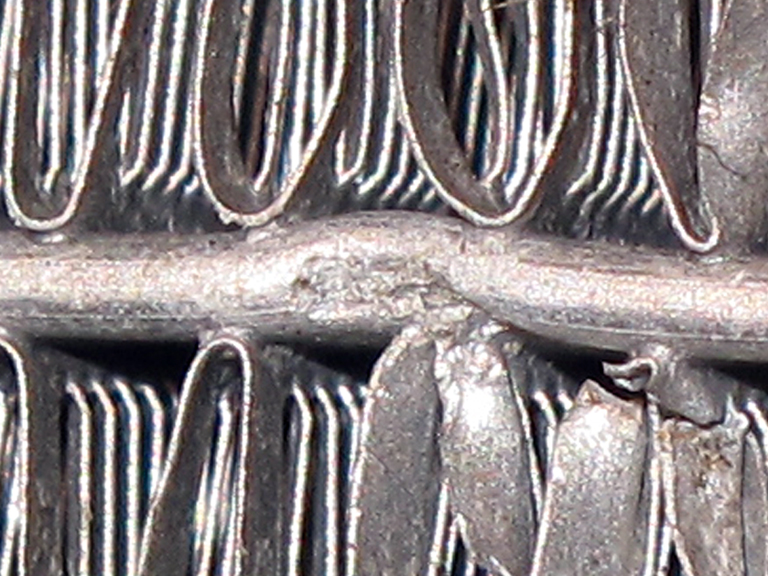

“road debris or rock hit the condenser causing the Freon to leak out”– This is very common for places that have had extensive road work or back road areas with old pavement or gravel and dirt roads. It is hard to fully protect your condenser since it needs to be an open area for fresh air to flow through it. That being said many manufactures produce front grills with very tight openings so debris cant get through to puncture.

“A fuse is blown causing the compressor to not get any power” – As simple as this one sounds it is often overlooked. If your compressor all of a sudden stops operating and you have zero clutch movement the first thing you should do is check your AC/ compressor fuse and relay are still good.

“Compressor is grinding while the clutch is operating and the bearings are bad” – Most ac compressors on a vehicle will last 8-12 years. This is similar to a residential compressor although automotive compressors are put through a lot of stress and heat being in a engine bay. The best way to check your bearings is to remove the serpentine belt and try to spin the AC clutch pulley by hand. Also try to wiggle the pulley and middle clutch part back and forth. This will indicate any bad wear or parts that are about to fail.

I hope you stay cool this summer, best of luck!

Thank you very much for this valuable and detailed post about air conditioning tips. I really don’t know much about these things. But I learned a lot from your post. Sometimes my car also has similar problems. Keep posting like this. This kind of post is very important. I will definitely share this.

Thank you!